CNC machine with top side boring, grooving, cutting panel in line and shape could be done just in one process.

Flexijet 3D

Flow Nanojet Waterjet Cutter

Flow Mach 100 Series Waterjet Cutting Machine

Flow Mach 200 Series Waterjet Cutting Machine

Flow Mach 300 Series Waterjet Cutting Machine

Flow Mach 500 Series Waterjet Cutter

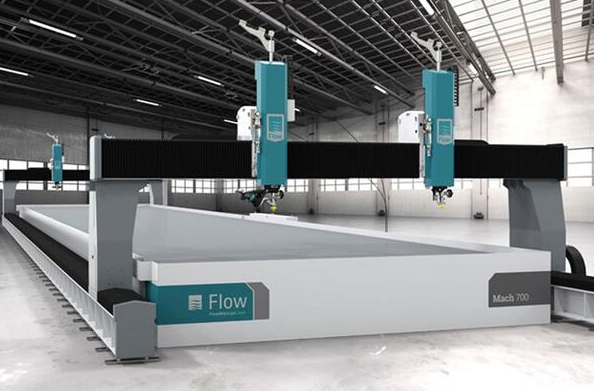

Flow Mach 700 Series Waterjet Cutter

Flow Advanced Solutions Waterjet Cutting

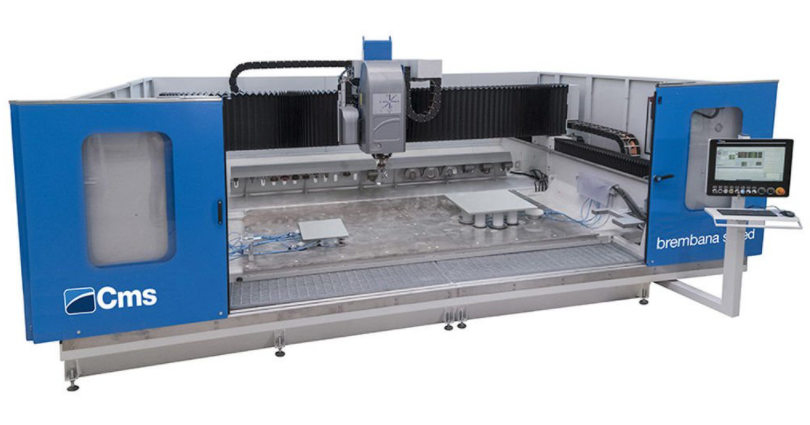

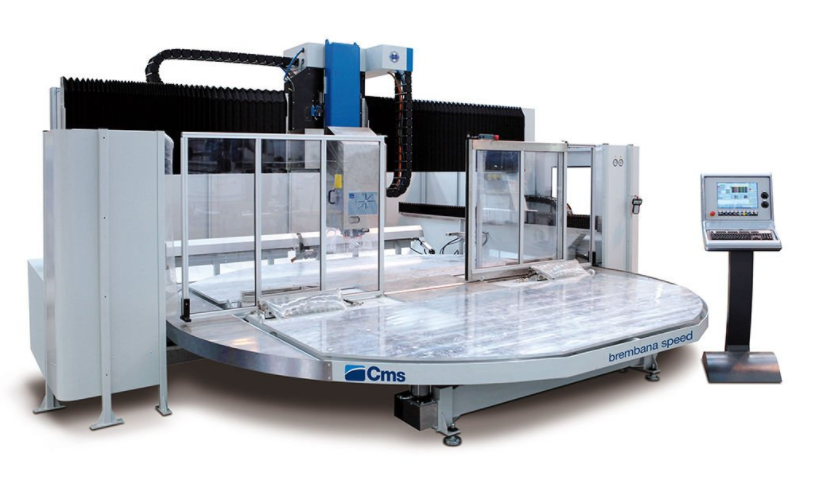

CMS Brembana Speed CNC Machine

CMS Brembana Maxima CNC Machine

CMS Brembana g-rex CNC Machine

CMS Brembana Speed tr CNC Machine

Fraccaroli & Balzan Waste Water Filtration Plant - SQUARE MODEL - FB/2000V-WDC

PLANT FOR DECANTATION AND RECYCLING OF WASTE WATER AND FOR MUD DEHYDRATION Mod. FB/2000V-WD

Max. treatment capacity up to 500 l/min of waste water

WASTE WATER PUMP

Submersed pump.

Equipped with:

delivery pipe attachment;

rubber hosing;

connection cable for the start up.

AUTOMATIC FLOCCULANT STATION

Container

"Open air" container for mixing the flocculant, built in steel plate.

Equipped with:

attachment support for electric mixer;

steel section supports, complete with anchorages.

Helical electric mixer

Low speed mixer, designed for maximum utilization of separation properties of flocculant.

Power : kW 0.37

Speed : r.p.m. 70

Mixing shaft diameter : mm 30

Flocculant dosing pump

Nr. 1 piston motor-driven pump type FB 100 DL for batching with adequate delivery to the plant, for programming according to specific requirements.

Power : kW 0.37

Flow rate : l/h 0100

Maximum pressure : Bar 8

Equipped with:

gearbox body in aluminium;

head body in PVC;

ARNITE piston (diam. 70 mm);

flocculant delivery hose in wired rubber (max. pressure 10 bar, diam. 1/2");

bronze non return valve.

WASTE WATER DECANTATION UNIT

Static decanter

Decanter built in steel plate.

Diameter : mm 2.000

Cross section : mm 2.200 x 2.200

Overall height dimensions : mm 5.100

Equipped with:

flanged overflow channel for recovery of decanted water;

central pipeline for inlet of turbid water into distribution cone;

internal pressure-off cone to facilitate sedimentation of solids contained in the water;

distribution cone support beam built in section steel;

steel delivery pipe, including flanges and curves;

manual valve type FB 50 for regulating the waste water flow, fitted internally with anti-abrasive rubber sleeve;

steel collection pipe for treated water, including flanges and curves.

Internal decanter treatment

The decanter is internally lined with a corrosion proof, anti-abrasive and stick-proof lining. This lining protects the metal from incrustations and allows easy detaching of the sludge from the walls, in order to prevent system clogging.

AUTOMATIC MUD DISCHARGE

Equipped with:

manual valve FB 100 M;

pneumatic valve FB 100 P complete with rubber anti-abrasive sleeve;

solenoid exhaust valve for pneumatic cylinder pressure;

flange (diam. 100 mm) with rubber support for piping connection;

probe group for automatic pump operation and automatic decanter discharge

CLEAN WATER RESERVOIR

Steel container for decanted water (capacity 5,000 l) incorporated in the decanter structure

FILTERPRESS, Mod. FB/300-5 (Treatment capacity 0,011 m3 /cycle of dry mud)

Filterpress structure

Structure in electro-welded composite steel, specially processed to guarantee perfect machine operation.

Sliding filter plate supported by 2 wheels with PVC bushing, which slide on the head tie rods, and 2 contrast wheels.

Hydraulic power unit

Hydraulic power unit for feeding the cylinder. Hydraulic cylinder for opening and closing plates, equipped with sealing rings type Polipac.

Plates

Nr. 5 polypropylene plates sliding on PVC plates and dragged by chains.

Plate size : mm 300 x 300

Automatic system for dragging the plates and opening the chambers, with external support in hardened steel for shaking and discharging the mud panels.

Set of filter clothes and under clothes.

Drainage tubes from the two lower side angles of the plates for conveying filtered water to the collection channel.

Filtered water collection channels with flow regulator, complete with consenting probes which determine the end of the filtering process.

Shaker for the plates

Square-section shafts (mm 40x40), each one supported externally by nr. 1 support mounted on bearings.

Equipped with:

hardened cams for shaking inserted on the shaft;

nr. 1 central supports with PVC bushing;

reduction gear unit (power kW 0.18) with self-arresting motor;

adjustable disc for locking into the proper position

Anti splash hood

Anti-splash hood built in pressed plate and fitted onto the filter press structure.

Mud feeding system to the filterpress

Steel container for sludge collection, complete with probe fittings.

Equipped with:

probe group for functioning of the filterpress;

reinforced rubber hose (max. pressure 10 atm).

High pressure feeding membrane pump.

Features:

Max. flow rate : l/min 100

Max. pressure : atm 7

ELECTRIC PANEL BOARD

Electric panel board manufactured in painted steel plate with door locked by a main switch, according to current safety norms.

Equipped with:

remote controls for every use;

PLC

Colour of the machinery: GREY RAL 7044 + RED RAL 3000

VOLTAGE: 400 V - 50 Hz

FRACCAROLI & BALZAN WASTE WATER FILTRATION PLANT - ROUND MODEL - FB/2300V-WDC

PLANT FOR DECANTATION AND RECYCLING OF WASTE WATER AND FOR MUD DEHYDRATION Mod. FB/2300V-WD

Max. treatment capacity 750 l/min of waste water

WASTE WATER PUMP

Submersed pump.

Equipped with:

delivery pipe attachment;

rubber hosing;

connection cable for the start up.

AUTOMATIC FLOCCULANT STATION

Container

"Open air" container for mixing the flocculant, built in steel plate.

Equipped with:

attachment support for electric mixer;

steel section supports, complete with anchorages.

Helical electric mixer

Low speed mixer, designed for maximum utilization of separation properties of flocculant.

Power : kW 0.37

Speed : r.p.m. 70

Mixing shaft diameter : mm 30

Flocculant dosing pump

Nr. 1 piston motor-driven pump type FB 100 DL for batching with adequate delivery to the plant, for programming according to specific requirements.

Power : kW 0.37

Flow rate : l/h 0 100

Maximum pressure : Bar 8

Equipped with:

gearbox body in aluminium;

head body in PVC;

ARNITE piston (diam. 70 mm);

flocculant delivery hose in wired rubber (max. pressure 10 bar, diam. 1/2");

bronze non return valve.

WASTE WATER DECANTATION UNIT

Static decanter

Decanter built in steel plate.

Features

Diameter : mm 2.300

Overall height dimensions : mm 6.250

Equipped with:

flanged overflow channel for recovery of decanted water;

central pipeline for inlet of turbid water into distribution cone;

internal pressure-off cone to facilitate sedimentation of solids contained in the water;

distribution cone support beam built in section steel;

steel delivery pipe, including flanges and curves;

manual valve type FB 50 for regulating the waste water flow, fitted internally with anti-abrasive rubber sleeve;

steel collection pipe for treated water, including flanges and curves.

Internal decanter treatment

The decanter is internally lined with a corrosion proof, anti-abrasive and stick-proof lining. This lining protects the metal from incrustations and allows easy detaching of the sludge from the walls, in order to prevent system clogging.

AUTOMATIC MUD DISCHARGE

Equipped with:

manual valve FB 100 M;

pneumatic valve FB 100 P complete with rubber anti-abrasive sleeve;

solenoid exhaust valve for pneumatic cylinder pressure;

flange (diam. 100 mm) with rubber support for piping connection;

probe group for automatic pump operation and automatic decanter discharge

FILTERPRESS, Mod. FB/400-6 (Treatment capacity 0,020 m3 /cycle of dry mud)

Filterpress structure

Structure in electro-welded composite steel, specially processed to guarantee perfect machine operation.

Sliding filter plate supported by 2 wheels with PVC bushing, which slide on the head tie rods, and 2 contrast wheels.

Hydraulic power unit

Hydraulic power unit for feeding the cylinder. Hydraulic cylinder for opening and closing plates, equipped with sealing rings type Polipac.

Plates

Nr. 6 polypropylene plates sliding on PVC plates and dragged by chains.

Plate size mm 400 x 400

Automatic system for dragging the plates and opening the chambers, with external support in hardened steel for shaking and discharging the mud panels.

Set of filter clothes and under clothes.

Drainage tubes from the two lower side angles of the plates for conveying filtered water to the collection channel.

Filtered water collection channels with flow regulator, complete with consenting probes which determine the end of the filtering process.

Shaker for the plates

Square-section shafts (mm 40x40), each one supported externally by nr. 1 support mounted on bearings.

Equipped with:

hardened cams for shaking inserted on the shaft;

nr. 1 central supports with PVC bushing;

reduction gear unit (power kW 0.18) with self-arresting motor;

adjustable disc for locking into the proper position

Anti splash hood

Anti-splash hood built in pressed plate and fitted onto the filter press structure.

Mud feeding system to the filterpress

Steel container for sludge collection, complete with probe fittings.

Equipped with:

probe group for functioning of the filterpress;

reinforced rubber hose (max. pressure 10 atm).

High pressure feeding membrane pump.

Features:

Max. flow rate : l/min 100

Max. pressure : atm 7

ELECTRIC PANEL BOARD

Electric panel board manufactured in painted steel plate with door locked by a main switch, according to current safety norms.

Equipped with:

remote controls for every use;

PLC

Colour of the machinery: GREY RAL 7044 + RED RAL 3000

VOLTAGE: 400 V - 50 Hz